Quality

Waterjet Newsletter – 06/24/2008

Effectiveness

of Helmet and Face Shield For Waterjetting

Protection Katakura and Guo*

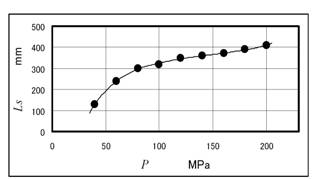

presented a research study in this subject, aiming to provide data necessary

for establishing industrial safety standards. A waterjet

with a diameter of 0.2 mm and up to 200 MPa

pressure was used in this study. Commonly used industrial safety helmets were

cut in halves and then impacted with the jet at different angles, different

stand-off distances, and different pressures. The helmet is made from

fiber-reinforced plastics (FRP). Its thickness varies between 1.4 mm and 2.8

mm. The face shield was simulated with 2 mm thick acrylic resin plates. The

time from the jet exiting the nozzle till penetration was recorded with a

hand-operated stop watch. Jetting was stopped after 30 seconds if no

penetration occurred. The results are summarized as

follows: o

No penetration occurred on the helmet within 30 seconds of

impact if the jet is 200 mm away, shotting at the

front of the helmet, and the pressure is below 40 MPa.

o

Penetration occurred 100% on the helmet within 30 seconds

of impact if the jet is only 100 mm away, shotting

at the front of the helmet, and the pressure is above 100 MPa.

o

When the pressure reached 200 MPa,

the helmet was penetrated at the weakest spot within 30 seconds when the jet

was at 350 mm or within 10 seconds when the jet was at 320 mm. The helmet was not penetrated within

30 seconds when the jet was 410 mm or further away. o

The chance of penetration is higher if the jet hits the

side (instead of front) of the helmet. o

The jet aiming at an angle (instead of perpendicular to

the target surface) has a lower chance of penetration. o

The simulated Their conclusion was that the

commercially available helmets and face shields are useful protective devices

if the jet is kept at a suitable distance away. *

Katakura, H. and Guo, C. (2006) Research on

personal protective devices for water jetting operation --- performance of

head and face protectors, Proceedings of the 8th Pacific Rim

International Conference on Water Jet Technology, Oct. 10-12, Qingdao, China,

Paper 42. Beyong High Pressure l

Dr. Lydia Frenzel

will host a workshop on “Coatings Removal and Surface

Preparation by WaterJet Methods with emphasis on

Flash Rust” on August 18, 2008 at Megarust, |

|

QualJet LLC

Quality Waterjet Spare Parts Specialist · Quality

Waterjet Spare Parts o Meets/exceeds

OEM standards o 30%

longer operation life time than competing products · Extensive

Parts Coverage for: o Flow

style, IR Style o 40K/55K

pumps o Intensifiers

o On/off

valves o Cutting

head o Swivels · OEM

Expert o 20+

year waterjet OEM experience (via OH Precision) o Accept

small OEM order Durable, Compact 40K

PSI Pumps

· Long

operation lifetime · Highly

cost-effective · Light

weight and compact · Contact

us for o

Custom power end o

50K psi models o

Private labeling o

Custom design QualJet LLC

1-866-QUALJET (782-5538) Fax: 425-378-7776 Email: info@qualjet.com Website: www.qualjet.com To unsubscribe the

newsletter: unsubscribe@qualjet.com For newsletter archive: www.qualjet.com/Newsletter.htm

Copyright ©2005, QualJet LLC |

|

|