Quality

Waterjet Newsletter – 9/27/2005

A Hybrid Pump of Direct

Drive and Intensifier – An 22-year Old Idea From time to time, it is

interesting and necessary to look back to the history. WJTA has offered us

the convenience of reading the earlier literature by putting the proceedings

of the first four WJTA conferences online (www.wjta.org).

This article will review a paper by Nakaya et al.*,

presented on the 2nd WJTA conference. These two types of high-pressure

pumps are the most popular in the current waterjet industry: intensifier and

direct drive. Intensifier pumps have the advantage of easy adjustment of

operating pressure, while the direct drive pumps are superior in efficiency.

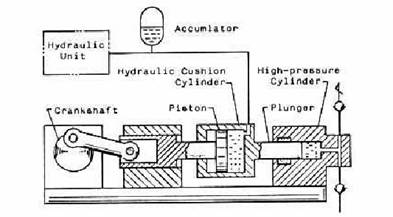

This paper described a hybrid pump of direct drive and intensifier. In this hybrid pump, as

illustrated in the following diagram, a hydraulic cushion cylinder was added

between the crankshaft and the plunger, compared to a typical direct drive

pump. The hydraulic pressure in the cushion cylinder P1 and the output water

pressure at the plunger side P2 follows the same principle as that of an

intensifier pump: P1×A1 = P2×A2. Therefore, the output pressure

P2 can be easily adjusted by changing P2 with a relief valve in the hydraulic

circuit.

Compared to an intensifier pump,

this hybrid pump has slightly higher efficiency (86% vs

77%). Its pressure pulsation is also less. The size of accumulator is only

70% of that in an intensifier pump. Compared to a direct drive pump, it gains

the advantage of easy pressure adjustment that is typically found on an

intensifier pump. Everyone can have his/her opinion

about this idea. Nevertheless, this paper is a great source of information if

you want to know how direct drive and intensifier pumps work. *Nakaya, M., Nishida, N., and

Kitagawa, T., “ Development of variable delivery triple reciprocating plunger

pump for water jet cutting,” Proceedings of the 2nd More For Less: Spare

Parts on · Flow-style High

Pressure Seal Kit (55K, 40K) at $90

(saving of $20). · Flow-style Check

Valve Body (55) at $260 (saving

of $55). · Flow-style Check

Valve Repair Kit (55K HO) at $68

(saving of $20). · IR-style On/Off

Valve Repair Kit at $100 (saving

of $15). · Contact info@qualjet.com |

|

QualJet

LLC

Quality Waterjet Spare Parts Specialist · Quality

Waterjet Spare Parts o Meets/exceeds

OEM standards o 30%

longer operation life time than competing products · Extensive

Parts Coverage for: o Flow

style, IR Style o 40K/55K

pumps o Intensifiers

o On/off

valves o Cutting

head o Swivels · OEM

Expert o 20+

year waterjet OEM experience (via OH Precision) o Accept

small OEM order Durable, Compact 40K

PSI Pumps

· Long

operation lifetime · Highly

cost-effective · Light

weight and compact · Contact

us for o

Custom power end o

50K psi models o

Private labeling o

Custom design QualJet LLC

1-866-QUALJET (782-5538) Fax: 425-378-7776 Email: info@qualjet.com Website: www.qualjet.com To unsubscribe the

newsletter: unsubscribe@qualjet.com For newsletter archive: www.qualjet.com/Newsletter.htm

Copyright ©2005, QualJet LLC |

|

|