Quality

Waterjet Newsletter – 09/26/2006

Enhanced

AWJ Cutting Through Modulation The research community of the

waterjet industry is constantly striving for improvement of productivity and

quality of cut. One of these efforts was from Henning and Westkamper*,

on enhancing AWJ cutting through modulation. Here are the highlights. Two main characteristics that

affect AWJ quality of cut are jet lag and striation marks. Striation marks

mainly affect the appearance of the part while jet lag will cause inaccuracy

around corners and small arcs. Currently reduction of jet lag and striation

are done by reducing the cutting speed. In this experimental study, three

kinds of modulation were tested, targeting reduction of jet lag and striation

without reducing the cutting speed. Two of these were done by superimposing a

constant linear cutting speed with a sine-oscillation, parallel or

perpendicular to the cutting direction.

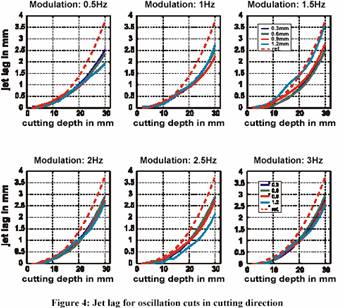

The average cutting speed was kept unchanged. The oscillation

frequency varied from 0.5 to 3 Hz and amplitude from 0.3 to 1.2 mm. The third

modulation was done by periodically interrupting the abrasive flow while

maintaining the same average flow rate. The interruption frequency was 1 Hz. The

proportion of Off time-vs-On time varied from 1:2

to 1:10. Among the three modulations, the

parallel oscillation has the most favorable impact on jet lag and striation.

Significant jet lag reductions were shown for all the tested oscillation

frequencies and amplitudes while low frequencies were slightly better (see

below*).

Perpendicular oscillation and

abrasive modulation also showed slight reduction of jet lag. Striation

magnitude was also reduced with parallel oscillation, but not as significant

as the jet lag reduction. Small oscillation amplitudes (0.3 and 0.6 mm) and

high frequency (2.5 Hz) produced the best result for striation reduction.

Striation got worse with perpendicular oscillation and toggling abrasive had

a mixed result, with the best result achieved at 1:6 OFF/ON ratio. For

overall performance parallel oscillation at high frequency and low amplitude

was recommended. * Henning,

A. & Westkamper, E. (2003) Modulation of

cutting operation with abrasive waterjets, Proceedings

of the 2003 WJTA American Waterjet Conference, Houston, Texas, USA, August

17-19, Paper 5-G. |

|

QualJet

LLC

Quality Waterjet Spare Parts Specialist · Quality

Waterjet Spare Parts o Meets/exceeds

OEM standards o 30%

longer operation life time than competing products · Extensive

Parts Coverage for: o Flow

style, IR Style o 40K/55K

pumps o Intensifiers

o On/off

valves o Cutting

head o Swivels · OEM

Expert o 20+

year waterjet OEM experience (via OH Precision) o Accept

small OEM order Durable, Compact 40K

PSI Pumps

· Long

operation lifetime · Highly

cost-effective · Light

weight and compact · Contact

us for o

Custom power end o

50K psi models o

Private labeling o

Custom design QualJet LLC

1-866-QUALJET (782-5538) Fax: 425-378-7776 Email: info@qualjet.com Website: www.qualjet.com To unsubscribe the

newsletter: unsubscribe@qualjet.com For newsletter archive: www.qualjet.com/Newsletter.htm

Copyright ©2005, QualJet LLC |

|

|