Quality

Waterjet Newsletter – 05/22/2007

Deep Hole

Drilling with AWJs Drilling a 300-mm-deep,

19-mm-diameter hole in tungsten with EDM takes over 40 hours. But how would

you do it otherwise? Hashish* proposed doing it with abrasive waterjets.

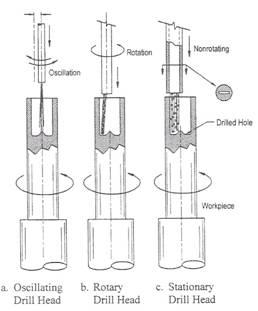

Three methods of deep hole

drilling were illustrated in the diagram. A series of drilling tests were

done with an oscillating jet and a rotating workpiece.

A 30.5-mm-deep hole was drilled on a tungsten rod at the rate of 160 mm/hr,

with a 0.330-mm-diameter jet at 345 MPa of pressure

and 3.75 g/s of mesh 100 garnet. By manipulating the oscillation frequency

and the rotational speed, the bottom face of the hole can take the shape

between high-in-the-center to high-at-the-rim. A computer simulation study of

the jet path coverage showed that, to achieve an even coverage of the entire

drilling face, the ratio of the oscillation frequency and the rotational

speed should not be an integer. An alternation to the first method is to

rotate a radially offset jet instead of oscillation.

It was found that the implementation was easier. Similar to the oscillation

method, the ratio of the two rotational speeds should not be an integer. The

geometry at the bottom of the hole can be manipulated to some degree by

changing the offset value. Ideally the diameter of the drill should be

roughly equal to the required radius of the hole. The jet had a 3° angle to

the rotational axis in this study. Experiments with a non-rotary rectangular

jet and a rotating workpiece were also done.

Multiple parallel waterjets shot through a

rectangular mixing tube. Different sizes of jets can be used to achieve a

desired power gradient for geometrical purpose - a flat bottom is possible. A

drilling rate of 115 mm/hr was achieved on tungsten with two 0.254-mm-diameter

jets (equivalent to one 0.330-mm-diameter jet in power consumption). Higher drilling rates can be

achieved by increasing pressure and abrasive flow rate. Test results showed

that drilling rate can reach 457 mm/hr for steels and 305 mm/hr for tungsten.

With these methods, drilling holes with thin walls is possible. However to

minimize the hole diameter variation, an adaptive control system is needed to

match the advance speed to the material removal rate. A trial-and-error

approach can also be used. The AWJ-drilled holes have a high quality and are

relatively smooth with a typical Ra roughness of 2.2 micron. *

Hashish, M. (1996) Deep hole drilling in metals using abrasive waterjets, in Colin Gee (ed.), Proceedings of the 13th

International Conference on Jetting Technology, Sardinia, Italy, October

29-31, pp 691-707. |

|

QualJet LLC

Quality Waterjet Spare Parts Specialist · Quality

Waterjet Spare Parts o Meets/exceeds

OEM standards o 30%

longer operation life time than competing products · Extensive

Parts Coverage for: o Flow

style, IR Style o 40K/55K

pumps o Intensifiers

o On/off

valves o Cutting

head o Swivels · OEM

Expert o 20+

year waterjet OEM experience (via OH Precision) o Accept

small OEM order Durable, Compact 40K

PSI Pumps

· Long

operation lifetime · Highly

cost-effective · Light

weight and compact · Contact

us for o

Custom power end o

50K psi models o

Private labeling o

Custom design QualJet LLC

1-866-QUALJET (782-5538) Fax: 425-378-7776 Email: info@qualjet.com Website: www.qualjet.com To unsubscribe the

newsletter: unsubscribe@qualjet.com For newsletter archive: www.qualjet.com/Newsletter.htm

Copyright ©2005, QualJet LLC |

|

|