Quality

Waterjet Newsletter – 03/20/2007

AWJ Cutting of Engineering Plastics Abrasive Waterjet (AWJ) can

effectively cut hard materials such as tool steels. So we know that it has no

problem in cutting plastics. However, we don’t really know the characteristics

of plastic parts cut with AWJs. Last year Seo

and Ramulu* presented a paper on this subject. This

review will share their main findings. Their paper described an

experimental study of cutting a thermoplastic material MC901 nylon with AWJs. The experimental conditions include water pressure

of 250-320 MPa, 80 mesh garnet

at 7.8 g/sec flow rate, stand-off distance of 2-5 mm, and cutting speed

between 33 and 1350 mm/min. The maximum cutting speed is 1350 mm/min for a 15

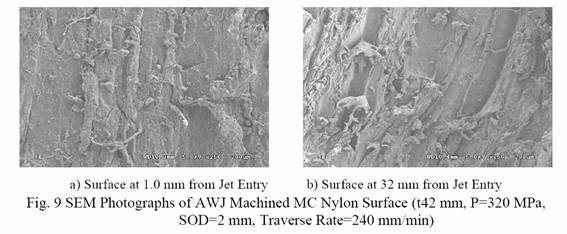

mm thick MC nylon. Surface roughness Ra is in the range of 3 to 36.7 mm, greater than that of metals. By examining the cut surfaces

under scanning electronic microscope (SEM), it was found that the material

removal mechanism of MC nylon is shearing due to scooping, scratching, and

plowing actions of the abrasive particles. Compared to metals, the scratched

marks of MC nylon appeared to be more protruded and rounded, probably due to

the visco-elastic and plastic nature of the plastic

materials with long polymer chains. The polymer chains tend to align with the

direction of shearing and remain attached to the cut surfaces as micro burrs

(see pictures below). As a result, the surface texture deteriorated. By

analyzing the roughness profile, it was found that the AWJ cut surface of MC

nylon is negatively-skewed, with peaks and valleys caused by scratch marks

and micro burrs. The ratio of the two roughness parameters Rq/Ra is about 1.24, closely

resembling that of grinding (1.2).

* Seo, Y.W. & Ramulu, M.

(2006) Characteristics of abrasive waterjet machined engineering plastics

(nylon), in Wang et al. (ed.), Proceedings of the 8th Pacific Rim

International Conference on Water Jet Technology & The 12th

China Water Jet Technology Symposium, Qingdao, China, October 10-12, Paper 26. Beyond High

Pressure

|

|

QualJet

LLC

Quality Waterjet Spare Parts Specialist · Quality

Waterjet Spare Parts o Meets/exceeds

OEM standards o 30%

longer operation life time than competing products · Extensive

Parts Coverage for: o Flow

style, IR Style o 40K/55K

pumps o Intensifiers

o On/off

valves o Cutting

head o Swivels · OEM

Expert o 20+

year waterjet OEM experience (via OH Precision) o Accept

small OEM order Durable, Compact 40K

PSI Pumps

· Long

operation lifetime · Highly

cost-effective · Light

weight and compact · Contact

us for o

Custom power end o

50K psi models o

Private labeling o

Custom design QualJet LLC

1-866-QUALJET (782-5538) Fax: 425-378-7776 Email: info@qualjet.com Website: www.qualjet.com To unsubscribe the

newsletter: unsubscribe@qualjet.com For newsletter archive: www.qualjet.com/Newsletter.htm

Copyright ©2005, QualJet LLC |

|

|