Quality

Waterjet Newsletter – 03/06/2007

Optimum Water-Blasting If you want to achieve optimum

performance in your water-blasting applications, you may want to check out a

2001 paper by Wright et al*. Here are the highlights of this paper. The power of the jet in water-blasting

is a function of pressure and flow. For a given capacity of power, is it

better off to run a small orifice at high pressure or a large orifice at low

pressure? What is the role of stand-off distance? Wright et al. conducted an

experimental study to provide answers to these questions. Tests were done with pressures

from 5,000 to 33,000 psi, flows from 5 to 45 gpm, orifice sizes from 0.028” to 0.156”, and stand-off

distance from 2 to 50 inches. A machinable wax with

a threshold pressure of 5,000-6,000 psi and a

cement/sand mixture with a threshold pressure of 1,500 psi

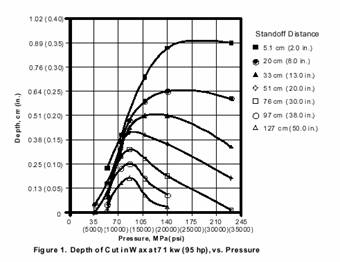

were used as the test samples. During the tests, passes were Data show that an increase in

stand-off distance will reduce the depth of kerfs and there exists an optimum

pressure for a given stand-off distance (Figure 1*).

* Wright,

D., Wolgamott, J., & Zink, G. (2001) Optimizing

water blast power, in Mohamed Hashish (Ed.), Proceedings of the 2001 WJTA

American Waterjet Conference, Minneapolis, Minnesota, USA, August 18-21,

Paper 49. Beyond High

Pressure

|

|

QualJet

LLC

Quality Waterjet Spare Parts Specialist · Quality

Waterjet Spare Parts o Meets/exceeds

OEM standards o 30%

longer operation life time than competing products · Extensive

Parts Coverage for: o Flow

style, IR Style o 40K/55K

pumps o Intensifiers

o On/off

valves o Cutting

head o Swivels · OEM

Expert o 20+

year waterjet OEM experience (via OH Precision) o Accept

small OEM order Durable, Compact 40K

PSI Pumps

· Long

operation lifetime · Highly

cost-effective · Light

weight and compact · Contact

us for o

Custom power end o

50K psi models o

Private labeling o

Custom design QualJet LLC

1-866-QUALJET (782-5538) Fax: 425-378-7776 Email: info@qualjet.com Website: www.qualjet.com To unsubscribe the

newsletter: unsubscribe@qualjet.com For newsletter archive: www.qualjet.com/Newsletter.htm

Copyright ©2005, QualJet LLC |

|

|